Cottonseed Oil Manufacturing Plant Process Flowchart

We are your reliable manufacturer of cottonseed oil manufacturing plant. Quality, technology and service are three things that we always focus on as our

Production and Processing of Quality Cotton Seed | SpringerLink

After harvesting, preparation of seed cotton for ginning by immediate drying below 12% moisture content separates lint of good staple length and strength without affecting the seed coat. Cotton seed is further subjected to drying up to 8% moisture content and processing (Usberti et al. 2006 ).

Cottonseed oil

Cottonseed oil is cooking oil from the seeds of cotton plants of various species, mainly Gossypium hirsutum and Gossypium herbaceum, that are grown for cotton fiber, animal feed, and oil. Cotton seed has a similar structure to other oilseeds such as sunflower seed, having an oil-bearing kernel surrounded by a hard outer hull; in processing, th

(PDF) The Effect of Process Variables on the ... - ResearchGate

The optimization of biodiesel production from a Typical Nigerian cottonseed oil using sodium hydroxide as catalyst is presented. 23 factorial design was employed to study the combined effect of

9.11.1 Vegetable Oil Processing US EPA

9.11.1.2 Process Description6-9 The following process description discusses only soybean oil manufacture, because emission factors are available only for that activity. Corn,

Steps of Cottonseed Oil Processing Process | Oilmillmachinery.net

Cottonseed oil is a vegetable oil extracted from the seeds of the cotton plant after the cotton lint has been removed. It composed of linters (10%), cotton shell (40~45%) and kernel. the oil content of cotton seed is 15%-25%, the oil content of kernel is 30%-40% after decorticating.

Overcoming the processing challenges of cottonseed oil

The oil’s cooking potential was driven by popular products like Crisco, which was short for “crystallized cottonseed oil,” and Wesson cooking oil. Although

Cottonseed oil

Cottonseed oil processing steps Cottonseed oil, like other vegetable oils, is extracted from the seed of the plant, through either mechanical processes such as crushing or pressing, [53] or by chemical processes such as solvent extraction. [54] Cottonseed oil is most commonly extracted commercially via solvent extraction. [55] Use in food

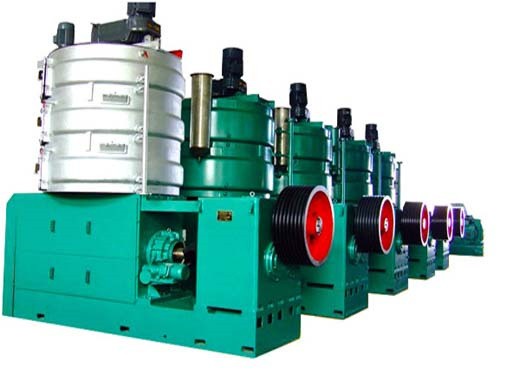

Complete Equipment and Machinery for Cottonseed

Removing the Hulls. Hulls makeup about 40% to 55% percent of cottonseeds and also has 0.3% to 1% oil. You can get 14% to 25% oil from cottonseed and 30% to 40% oil from

9.11.1 Vegetable Oil Processing - U.S. Environmental

The processfor soybeans typically consists of five steps: oilseed handling/elevator operations, preparation ofsoybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oilrefining. Oilseed Handling/Elevator Operations -